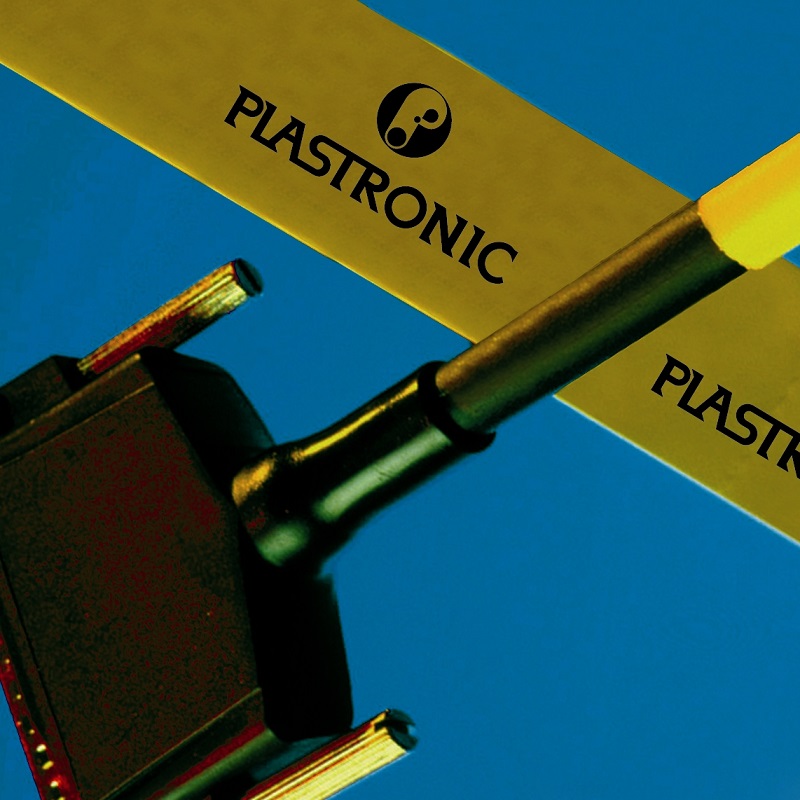

CT300 Printable Flattened Heat Shrink Tubing

£161.75 – £1,176.98 (incl. VAT)

From £161.75

CT300 is flattened, heat shrinkable tubing intended for wire and cable identification and is available in continuous spools.

Description

CT300 is flattened, heat shrinkable tubing intended for wire and cable identification and is available in continuous spools. This printable sleeving is designed for computer-based printing and is formatted for applications where in-sequence kitting is not of over-riding importance, for example where several hundred identical markers are required.

Large pack sizes, usually 100m (328 feet), minimise the number of spool changes necessary during production runs. CT300 identification tubing is made from durable, flame retarded radiation-crosslinked heat-shrinkable polyolefin. It meets the performance requirements of AMSDTL-23053/5 classes 1 and 3.

The identification marks are permanent immediately after printing and remain legible even when exposed to solvents, fuels, and oils. CT300 meets the mark permanence requirements of AS-81531 and MIL-STD-202F Method 215 both before and after shrinking.

This product has a 3:1 shrink ratio (except sizes 38.1 and 50.8 which are 2:1) and covers a wide range of wire diameters, thus simplifying inventory. It shrinks extremely rapidly, so installation is fast and economical. The installed markers are low profile and lightweight. They may be used to provide strain relief and insulation in addition to identification.

Features and benefits

- Continuous format heat-shrinkable identification tubing.

- Very flat.

- Computer printable.

- Military specification material and print performance.

- 3:1 shrink ratio – All sizes up to 1″

- 2:1 shrink ratio – Sizes 1-1/2″ & 2″

- UL224 VW-1 rated

Temperature rating

Operating temperature range: -55°C to +135°C

Minimum recovery temperature: 85˚C

Maximum storage temperature: 40˚C

Specifications/approvals

UL E35586

CSA LR31929

RoHS Compliant

Additional information

| Diameter (mm) | 2.4, 3.2, 4.8, 6.4, 9.5, 12.7, 19.0, 25.4, 38.0, 51.0 |

|---|---|

| Colour | White, Yellow |

| Length (m) | 50, 100 |

| Brand | Plastronic, TE Connectivity |

| Max operating temperature | 135 |

| Shrink ratio | 3:1 |

| Specification | CSA, LR31929, Reach, RoHs, UL224 |

My account

My account