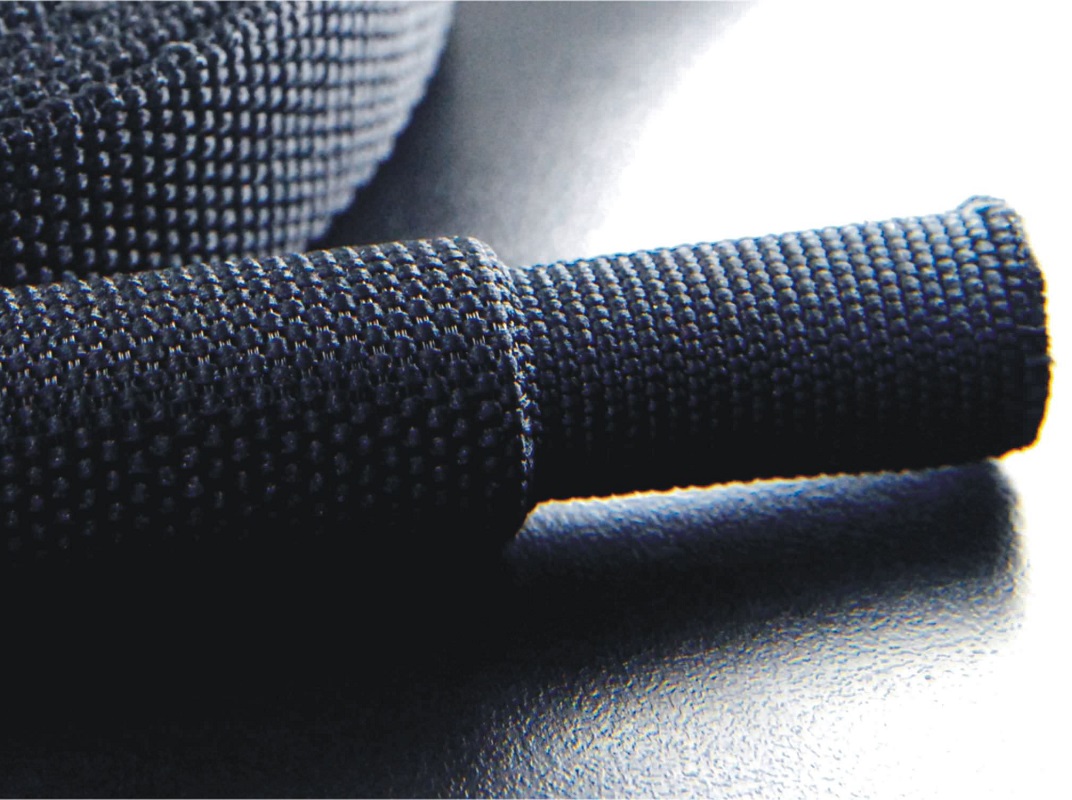

PPS-HSS Heat Shrinkable Fabric Sleeving

£77.50 – £327.63 (incl. VAT)

From £77.50

PPS-HSS is 2:1 heat-shrink fabric sleeving. It combines a woven polyester multifilament with a modified polyolefin filament. This means outstanding abrasion performance, fast and easy installation (saving time & money) combined with a higher thermal rating (3,000 hours at 150c). It’s also zero halogen.

Please note: this product is available on an 8-week lead time.

Description

PPS-HSS is 2:1 heat-shrink fabric sleeving that combines a woven polyester multifilament with a modified polyolefin filament.

The woven yet heat-shrinkable design makes it easy to install, ideal for awkward rubber hoses and wire harnesses with irregular shapes and tight bends. A faster installation saves you time and money.

Unlike PPS-HSS, standard (non-shrink) braided sleeving needs to be fixed in place, often with rubber bands, which in turn can cause abrasion issues. Instead, when in place, PPS-HSS is shrunk to conform to its substrate either with a standard heat gun (low volume applications) or in tunnel/static ovens (high volume applications). No extra fixing and no abrasion.

Some polyolefin braided sleeving can also raise concerns due to limited thermal performance above 80c, particularly in engine bay hotspots. PPS-HSS has a higher thermal rating, ie 3,000 hours at the 150c maximum operating temperature. Additionally, PSS-HSS is zero halogen (less smoke/outgassing) which again makes it ideal for use in environments such as engine bays.

To sum up, PPS-HSS is the ideal heat shrink fabric sleeving for abrasion resistance and noise reduction in harsh conditions. And it can be used as an alternative for the similar product HFT5000.

Additional information

| Diameter (mm) | 10, 12, 20, 30, 34, 40, 50, 60, 70, 80, 100 |

|---|---|

| Colour | Black |

| Length (m) | 50, 100 |

| Shrink ratio | 2:1 |

| Specification | RoHs |

| Max operating temperature | 150 |

My account

My account